Home, Auto Repair Library, Auto Parts, Accessories, Tools, Manuals & Books, Car BLOG, Links, Index

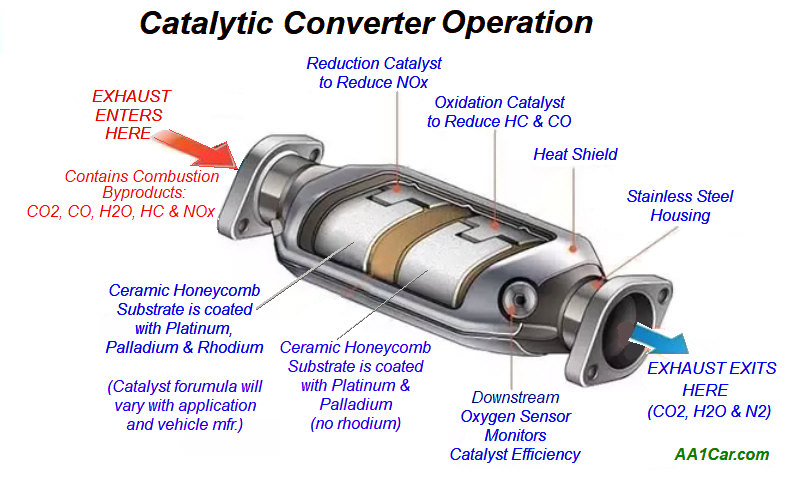

Catalytic converters are one of the greatest emission add-ons ever to be installed on vehicles. By cleaning up the pollutants left over from combustion, they reduce tailpipe emissions of hydrocarbons (HC) and carbon monoxide (CO) to extremely low levels (almost ZERO!) when everything is operating normally. But sometimes things do not operate normally, tailpipe emissions can go up, engine performance may suffer or your vehicle may not pass an emissions test.

Catalytic converters should last a long time, upwards of 150,000 miles or more under normal conditions. However, if the catalyst becomes contaminated it will stop functioning as an afterburner and emissions will go up. Also, the ceramic honeycomb inside the converter may become clogged with carbon deposits, creating a restriction and excessive backpressure that chokes engine performance. If the converter becomes completely plugged, it won't let the engine get rid of its exhaust gases, causing the engine to stall.

Driveability symptoms such as a drop in fuel economy, a loss of normal engine power, a rough idle or stalling immediately after starting the engine can all be signs of excessive backpressure caused by a plugged converter.

If the converter becomes contaminated with elements that are found in motor oil (phosphorus anti-wear additives) or antifreeze (silicate corrosion inhibitors), the catalyst will lose it ability to clean up the exhaust, causing an increase in hydrocarbon (HC), carbon monoxide (CO) and/or Oxides of Nitrogen (NOx) emissions. As a rule, when converter efficiency drops below 90 to 95 percent, it will set a catalyst efficiency code. A vehicle with an illuminated Check Engine Light and ANY trouble codes will NOT pass an emissions check,

A fouled converter may or may not cause an increase in backpressure, but eventually it might if carbon starts to build in the honeycomb restricting the passageways.

The important point to remember here is that converters don't just foul or plug up for no good reason. There is always an underlying cause which must be diagnosed and corrected before the problem can be eliminated. Identifying a plugged or fouled catalytic converter is only half the fix. Why? Because repl;acing a bad converter will only solve the current problem temporarily. If the underlying cause of the converter failure is not also diagnosed and repaired, sooner or later the new converter will likely suffer the same fate.

Under normal operating conditions, the converter should not have to work very hard to keep emissions to a minimum. If your engine has good compression, is not burning oil, and the fuel, ignition and engine management system are all working properly, the exhaust coming out of the engine should have relatively low levels of HC and CO (less than 0.01 percent CO and less than 50 ppm HC) when the engine is warm).

The average light off temperature at which a catalytic converter begins to function ranges from 400 to 600 degrees F. The normal operating temperature can range up to 1,200 to 1,600 degrees F. But as the amount of pollutants in the exhaust go up, so does the converter's operating temperature.

To reduce cold start emissions until the converter can heat up and start to work, many late model engines have small "Pre-Cat" or "Pup Cat" mini-converters in the aft part of the exhaust manifold or in the head pipe between the converter and manifold. Because they are mounted much closer to the engine, they heat up quickly and start to reduce emissions while the main converter is still warming up. The Pre-Cats are oxidation catalysts that reduce HC and CO. They do not affect NOx because NOx only occurs when the engine is hot and under load.

In late-model engines with multipoint fuel injection or direct fuel injection , combustion is so clean that the converter has little to do so the difference between the converter inlet and outlet temperature may only be 30 degrees F or so at 2,500 rpm - which is a lot better than the older first generation converters that typically had at least a 100 degree F differential between the inlet and outlet at cruise. At idle, the converter in many late-model vehicles may cool off so much that there's almost no measurable difference in temperature fore and aft. That's why checking exhaust temperatures fore and aft of the converter at idle and 2,500 rpm is NOT an accurate way to determine if the converter is good or bad.

What a temperature reading will tell you is if a converter is overheating. You can aim a handheld infrared pyrometer at the pipes just ahead and behind the converter with the engine running to see if it is running too hot. A difference in temperature readings fore and aft of 200 degrees F or more means trouble. Unburned fuel is getting into the exhaust and causing the converter to overheat. The most likely cause would be a misfiring spark plug, a bad coil-on-plug ignition coil, or a leaky exhaust valve. An overly rich air/fuel mixture (possibly due to a bad oxygen sensor or a leaky fuel injector) would be other possible causes to investigate.

Other causes of elevated tailpipe emissions may include lean misfire (check for vacuum leaks, leaky EGR valve, low fuel pressure or dirty injectors). A single misfiring spark plug can cause an increase in HC emissions of 2,500 or more parts per million, which can push the converter's operating temperature well above its normal range.

Another clue that the converter may be running too hot is a badly discolored or warped converter shell.

Prolonged overheating or short term severe overheating can damage the honeycomb substrate inside the converter, causing a partial collapse or even melting. The underlying cause here is often fouled or misfiring spark plugs, or a burned exhaust valve that leaks compression and allows unburned fuel to pass through the combustion chamber into the exhaust.

To diagnose a plugged catalytic converter, you can check intake vacuum or exhaust backpressure. To check intake vacuum, connect a vacuum gauge to a vacuum port on the intake manifold. Start the engine and note the vacuum reading at idle. Then increase engine speed to about 2,500 rpm and hold steady. Normal vacuum at idle for most engines should be 18 to 22 inches Hg. When the engine speed is increased there should be a momentary drop in vacuum before it returns to within a couple of inches of the idle reading. If the vacuum reading is 10 percent lower than normal and/or continues to drop as the engine runs, it probably indicates a buildup of backpressure in the exhaust. Remember, though, that intake vacuum can also be affected by retarded ignition timing and valve timing. What's more, some engines are much more sensitive to small changes in intake vacuum than others, so checking backpressure rather than intake vacuum may give you a better indication of what's going on.

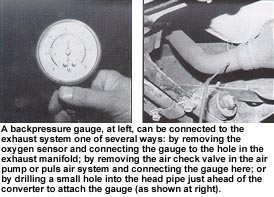

Checking backpressure requires connecting a pressure gauge to the exhaust system. Use a gauge that reads up to 8 to 10 psi and is calibrated in 1/2 inch increments. Or, use a metric pressure gauge calibrated in kilo-Pascals (kPa). One psi equals 6.895 kPa.

A backpressure gauge can be connected to the exhaust system one of several ways: by removing the oxygen sensor and connecting the gauge to the hole in the exhaust manifold; by removing the air check valve in the air pump or pulse air system and connecting the gauge here; or by drilling a small hole into the head pipe just ahead of the converter to attach the gauge (never drill a hole into the converter itself!). One drawback of drilling a hole is that the hole will have to be plugged by a self-tapping screw, plug or welded shut after you've taken your measurements. Also, drilling is not recommended if the head pipe has a double-wall construction.

Once you've made your connection, start the engine and note the backpressure reading. Depending on the application, the amount of backpressure that's considered "normal" will vary. On some vehicles, backpressure should read near zero at idle, and should not exceed 1.25 psi at 2,500 rpm. Others can handle 0.5 to 1.25 psi at idle, but should have more than 4 psi during a snap acceleration test.

If you find a relatively high backpressure reading (say 8 to 10 or more psi), there's obviously an exhaust restriction that will require further diagnosis. Don't jump to conclusions and assume the converter is plugged because it might be a collapsed pipe or muffler.

One way to rule out the pipes and muffler is to visually inspect the exhaust system for damaged components. Another way is to drill a small hole in the pipe aft of the converter and check backpressure here. If the reading is lower (or is less than about 1 psi), the rest of the system is OK and the converter is what is causing the restriction. Or, disconnect the exhaust pipe aft of the converter. No change in backpressure would indicate a blockage at or ahead of the converter. If backpressure drops back to normal, the problem is not the converter but a collapsed pipe or muffler.

If you suspect the converter is plugged, you can disconnect and remove it. Then hold a shop light by one end of the converter and look in the other end. If you can't see the light shining through the honeycomb, the converter is plugged and needs to be replaced.

You can also shake the converter. If you hear stuff rattling around inside, it means the honeycomb substrate is probably damaged, cracked or crumbling and falling apart.

There are several ways to detect a restricted, plugged or worn out converter using a scan tool. Here's what to look for

* A significant difference in Short Term Fuel Trim (STFT) and Long Term Fuel Trim (LTFT) values between the right and left cylinder banks on a V6, V8 or V10 engine. If you see such a difference and the vehicle has separate converters for each cylinder bank, one of the converters may be plugged.

* A lower than normal barometric pressure (BARO) value. If your engine has a Mass Airflow (MAF) sensor, and the engine computer uses the signal from the MAF sensor to calculate a barometric pressure (BARO) value, the calculated value may be lower than normal is the exhaust is restricted.

* A lower than normal Manifold Absolute Pressure (MAP) sensor value. A restricted converter will cause an increase in backpressure that reduces intake vacuum.

* A lower than normal Calculated Load value. The Calculated Load value (percentage or grams/second) displayed on a scan tool is a measure of the engine's volumetric efficiency. A low value means the engine isn't breathing normally because of an exhaust restriction.

* A P0420 to P0423 code. The converter may not be restricted, but it is not operating at normal efficiency. The OBD II system is really good at detecting a failing or bad converter, so if everything else if working okay and there are no exhaust leaks or O2 sensor problems, and you get a P0420 code, chances are your vehicle needs a new converter.

If your scan tool provides a "catalyst efficiency" readout, that would tell you if efficiency has dropped to the point where it is increasing emissions and setting a trouble code. An catalyst efficiency reading of 90 percent of less would tell you the converter is bad and needs to be replaced.

To clean the exhaust, the catalyst inside the converter must be exposed to the hot exhaust gases. Lead, phosphorous and silicone can contaminate the catalyst and prevent it from working its magic. Lead used to be the most common contaminant back in the late 1970s and early 1980s, but no more. Phosphorus is still a threat, and comes from motor oil. So if your engine is burning oil because of worn valve guides, worn valve guide seals or worn or damaged piston rings, phosphorus will shorten the life of your converter. Blue smoke in the exhaust and an emissions failure are pretty good clues that the converter has been fouled with phosphorus.

Motor oil suppliers began reducing phosphorus (ZDDP) levels back in 2005 to help prolong the life of converters. ZDDP is an anti-wear additive, but less is needed in today's engines with roller lifters and cam followers. Lowering ZDDP levels reduces the risk of converter contamination over time.

Silicates can find their way into the exhaust if the engine develops an internal coolant leak through a crack in a combustion chamber or a head gasket. Silicate corrosion additives can contaminate oxygen sensors as well as the converter, so chances are if the converter has been fouled by an antifreeze leak, the O2 sensors will also need to be replaced.

White smoke in the exhaust is a clue that there's an internal coolant leak.

Converter operating efficiency is monitored and calculated by the Powertrain Control Module (PCM) by comparing the upstream and downstream oxygen sensor readings. If the converter if working at peak efficiency, the downstream O2 sensor will show little activity. But if the converter is losing efficiency, the downstream O2 sensor will show an increase in activity. If that increase passes a certain threshold (which varies depending on the year/make/model of vehicle), it will set a trouble code and tun on the Check Engine Light.

There is no way for a do-it-yourselfer to easily check converter efficiency, but a repair shop or car dealer that has a 4- or 5-gas exhaust analyzer can get a direct readout on their equipment. Trouble is, most shops don't use exhaust analyzers much anymore, relying instead on the OBD2 system catalyst monitor to do that for them.

All 1996 and newer vehicles have OBD II onboard diagnostics to keep an eye on all the engine sensors, emission controls (including the converter) and engine performance. If it detects a problem that MIGHT cause emissions to increase 50 percent or more, it sets a trouble code and turns on the Check Engine Light.

The catalyst Monitor is part of that system, but it only runs when certain conditions have been met. The catalyst monitor may run when the vehicle is cruising at a steady highway speed of 40 to 60 mph for at least 10 minutes with the engine at normal operating temperature and in Closed Loop.

NOTE: The catalyst monitor will NOT run if there are any oxygen sensor fault codes present, or the oxygen sensor monitors have not completed.)

As we said earlier, the OBD II programming in the PCM compares O2 sensor readings upstream and downstream of the converter, and the converter's reaction time to a sudden change in the air/fuel mixture. If the converter is slow to respond, or the downstream O2 sensor readings don't flatten out and level off once the converter is hot and doing its thing, it will see that as a drop in operating efficiency and probably set a P0420 catalyst efficiency code.. Other converter faults may set codes ranging from P0420 to P0439.

P0420....Catalyst System Efficiency Below Threshold Bank 1

P0421....Warm Up Catalyst Efficiency Below Threshold Bank 1

P0422....Main Catalyst Efficiency Below Threshold Bank 1

P0423....Heated Catalyst Efficiency Below Threshold Bank 1

P0424....Heated Catalyst Temperature Below Threshold Bank 1

P0425....Catalyst Temperature Sensor Bank 1

P0426....Catalyst Temperature Sensor Range/Performance Bank 1

P0427....Catalyst Temperature Sensor Low Input Bank 1

P0428....Catalyst Temperature Sensor High Input Bank 1

P0429....Catalyst Heater Control Circuit Bank 1

P0430....Catalyst System Efficiency Below Threshold Bank 2

P0431....Warm Up Catalyst Efficiency Below Threshold Bank 2

P0432....Main Catalyst Efficiency Below Threshold Bank 2

P0433....Heated Catalyst Efficiency Below Threshold Bank 2

P0434....Heated Catalyst Temperature Below Threshold Bank 2

P0435....Catalyst Temperature Sensor Bank 2

P0436....Catalyst Temperature Sensor Range/Performance Bank 2

P0437....Catalyst Temperature Sensor Low Input Bank 2

P0438....Catalyst Temperature Sensor High Input Bank 2

P0439....Catalyst Heater Control Circuit Bank 2

If your converter needs to be replaced, it may be covered under warranty. You can take you vehicle to a new car dealer and have the converter replaced for free. However, you may be charged for other components such as oxygen sensors, pipes, clamps, etc.

The federal emissions warranty that applies to ALL cars sold in the U.S. covers the catalytic converter and PCM for 8 years or 80,000 miles (which ever comes first). Some states have their own emissions warranty requirements for vehicles that are sold and registered within that state, including California, Connecticut, Maine, Massachusetts, New Jersey, New York, Rhode Island and Vermont. In these states, the converter is covered for 7 years or 70,000 miles (which ever comes first). On PZEV certified hybrid vehicles, the warranty is even better: 15 years or 150,000 miles.

NOTE: Warranty coverage is from the vehicle build date, not its sale date or model year. The build date can be found on a decal or plate usually mounted on the center door pillar.

Aftermarket replacement converters have a shorter warranty of 2 years or 24,000 miles, and typically contain less catalyst and/or a shorter catalyst bed inside the converter shell. On some applications, they may not perform as well as the original and may cause the P0420 code to reset.

If the converter is plugged, contaminated, damaged or rusted out, it must be replaced. Likewise, if the OBD II system is showing low catalyst efficiency, the converter must be replaced.

On a dual-cat system, the side with the bad converter code will tell you which cylinder bank to check. If the converter on the right is bad, for example, check the O2 sensor, spark plugs and compression on the right cylinder bank.

Replacing the oxygen sensors at the same time is also recommended. Old, high mileage O2 sensors can become sluggish and slow to respond to changes in the Air/Fuel mixture. This, in turn, can affect the operating efficiency of the converter as well as the OBD2 catalyst monitor.

Related Articles:

Related Articles: Click Here See More Carley Automotive Technical Articles

Click Here See More Carley Automotive Technical Articles