Home, Auto Repair Library, Auto Parts, Accessories, Tools, Manuals & Books, Car BLOG, Links, Index

Tools & Equipment: Frequently Asked Questions

by Larry Carley copyright 2024 AA1Car.com

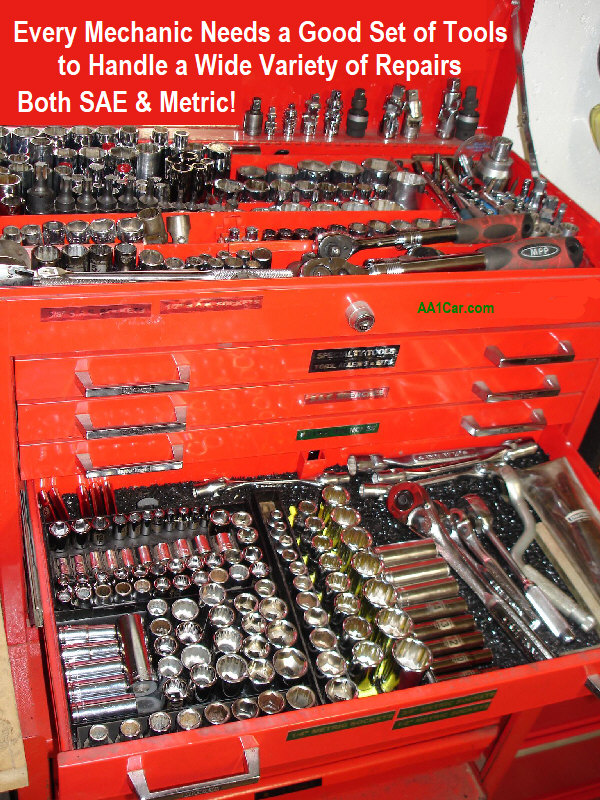

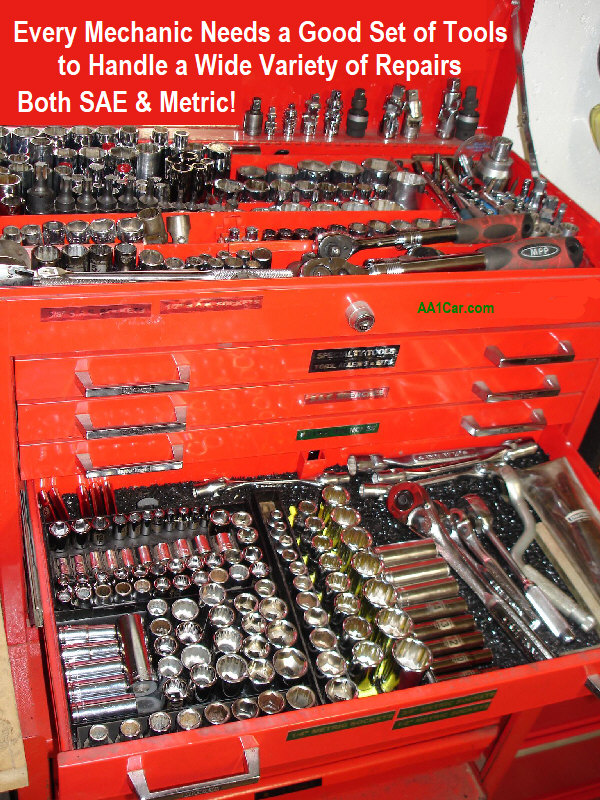

For a backyard DIY mechanic, some people can make do with a pair of Vice Grips, a couple of screw drivers, a roll of duct tape and a hammer. But for real repair work, you need the following tools:

* A quality set of open and box end wrenches

* A full set of standard and deep sockets with several extensions for a 1/4, 3/8 and 1/2 inch drive ratchet wrenches (SAE and/or metric depending on the vehicles you own)

* A torque wrench (any type)

* A range of pliers including regular and needle nose pliers, locking pliers and adjustable pliers

* An assortment of large and small screwdrivers (flat tip, Phillips and Torx drive)

* A ball peen hammer and some punches and chisels

* Some various size funnels and an oil catch pan

* A scan tool that can read trouble codes AND sensor data AND erase old codes

* A Digital Volt Ohm meter (DVOM)

* A floor jack (2-ton minimum) and a set of sturdy 4-leg safety stands. Do NOT use 3-leg stamped steel stands, cement blocks or stacks of wood

* A trouble light with a long extension cord, or a battery-powered bright LED light

* A pair of mechanics gloves for hand protection (latex or nitrile)

* Safety glasses or goggles to protect your eyes

* An accurate tire pressure gauge

* A foot pump or air compressor (mini or fullsize) for adding air to tires

* Smart battery charger (automatically senses battery voltage and varies charge rate)

* A cordless or pneumatic impact wrench (1/2-inch drive)

* A cordless or pneumatic ratchet wrench (3/8-inch and/or 1/2-inch)

* An air compressor (for pneumatic tools and/or spray paint gun)

* A cordless or pneumatic grinder/cutoff tool (great for exhaust work)

* A scan tool with graphing diagnostic capabilities (not just a code reader)

* A "creeper" for undercar work (saves your back and neck)

* An engine hoist for removing/installing engines in vehicles

* A transmission jack for removing/installing transmissions

* Various types of gear pullers and hub pullers (handy for replacing FWD shafts)

* Ball joint/tie rod end separator tools

* Exhaust pipe cutter and expander tools (for removing & installing exhaust pipes & mufflers)

* A two-post, four-post or scissor lift for undercar work (a big investment but makes so many jobs much easier and faster) Can also be used to stack vehicles for increased garage storage space if ceiling height permits

* A MIG welder for body & chassis work

* An acetylene torch for welding/cutting (take a basic welding course at local community college to get the most out of this kind of tool)

It depends on the job you need the tool for. Cordless tools have improved a great deal in recent years, with more powerful and longer lasting battery packs. Many brand name impact wrenches, ratchet wrenches and grinders can deliver as much if not more torque than their pneumatic counterparts.

The main advantages cordless tools have over pneumatic tools is there is no air hose to trip over, no need for a noisy air compressor in your garage, and no need to add oil to the air supply to keep the air tool lubricated.

The disadvantages of some cordless tools is that they can be heavier and bulkier depending on the size and capacity of the battery pack used. Smaller battery packs may also need to be recharged more frequently for prolonged heavy use. Professional grade cordless power tools and battery packs can also be much more expensive than their pneumatic counterparts.

For more info on this subject, see Cordless Power Tools: Can They Replace Pneumatic Tools?

With the key OFF, attach a DVOM or voltmeter to the battery terminals.

Set the DVOM or voltmeter to read VOLTS scale from 1 to 20 volts.

Touch the RED test meter lead to the positive (+) battery terminal

Touch the BLACK test meter lead to the negative (-) battery terminal.

The test meter will now display battery voltage.

Most car batteries should read about 12.65 volts if fully charged. If the battery reads less than 12.35 volts, it is low and needs to be recharged.

For more info, see Battery Testing & Recharging.

Start the engine and let it idle. Leave lights and other accessories OFF.

Set the DVOM or voltmeter to read VOLTS scale from 1 to 20 volts.

Touch the RED test meter lead to the positive (+) battery terminal

Touch the BLACK test meter lead to the negative (-) battery terminal.

The test meter will now display the charging voltage.

The charging voltage on most cars should be about 1.5 to 2.0 volts higher than the base voltage of the battery, or around 13.5 to 14.0 volts.

If the charging voltage is less than 13 volts, it may indicate a problem with the alternator.

Now turn on the headlights and see if the charging voltage changes. If it drops more than a volt, the alternator is not putting out sufficient voltage to meet the electrical needs of the vehicle and battery.

Need more info? See Charging System Checks.

First, do a visual inspection. Examine the wiring or connector for obvious damage or corrosion.

Next, inspect wiring connectors in suspected circuit for looseness, damage or corrosion. Repair or replace as needed.

If no obvious faults are seen, use a DVOM or voltmeter to check for a Voltage Drop across a connection.

Adjust the DVOM or voltmeter to read 0 to 1 volt (tenths of a volt).

Probe one side of the connection with the positive test lead, then the other side with the negative test lead. It does not matter which is which. The meter will read the same voltage drop either way.

Turn the vehicle on and turn on the item that is involved in the circuit in question (lights, wipers, electric motor, sensor, etc.). You want current flowing through the circuit so you can detect if any of that current is being restricted by a bad connection.

A good connection should show less than a 0.1 volt drop. On a high amp circuit like a starter motor or alternator, up to 0.4 or 0.5 volts may be acceptable. But anything higher indicates a poor connection and a need for cleaning, tightening and/or replacement.

for more info on this subject, see Voltage Drop Testing.

The primary use of a test light is to see if voltage is present in a circuit or at a connector.

A self-powered test light can also be used to check continuity in a 12-volt wiring circuit , but should NOT be used to test modules or electronics because the applied voltage may damage components!

Attach the test light ground connection to a good ground (bare metal) on the vehicle chassis, body or engine.

Use the other test light probe to touch the wire or connector terminal in question.

If the test light illuminates, voltage is present in the circuit. If there is no light, the circuit is dead.

The light by itself won't tell you how much voltage or current is in the circuit, only that enough voltage is present to illuminate the bulb in the tester.

A better test is to use a DVOM or voltmeter to measure voltage.

If the voltage reading is less than specifications (12 volts for lights, electric motors, powered accessories), there is a problem. For computer and sensor reference voltage circuits, 5 volts is usually the specified value.

An ohmmeter measures resistance (ohms). It can also be used to check continuity (the ability of a circuit or component to pass current).

IMPORTANT: NEVER connect an ohm meter (or DVOM set to read ohms) to a live circuit that contains voltage.

Always make sure the circuit is off (no voltage) before you attempt to measure resistance, otherwise you may damage your ohmmeter.

Resistance specifications vary greatly depending on what you are trying to measure. Adjust the scale on the ohmmeter to the appropriate range, then use the probes on the test meter to check the circuit or component.

To check the ON/OFF status of a switch:

A ZERO reading means the switch is closed (ON) and the circuit capable of conducting current.

An INFINITE reading means the switch is open (OFF) and the circuit is dead.

To check a wiring connection end-to-end, or the internal resistance of a component such as a light bulb, ignition coil, spark plug wire, electric motor, etc.

A ZERO reading means the wiring circuit or component has a short circuit (no resistance) and is probably defective. An INFINITE reading means the wiring circuit or component is open. The wiring or component is not conducting electricity and is probably defective.

A specific resistance reading (which may range from a few ohms to tens of thousands of ohms) tells you the wire or component is capable of conducting current and that it is not open or shorted. To tell if the reading is in or out of range, you have to compare your reading against the specifications for the component, wire or circuit you are testing. If the reading differs more than 10% from the specified range, the component, wire or circuit likely has a problem.

For additional help on testing electrical circuits, see the following:

Electrical Circuits

Electrical Loads for Automotive Systems, Lighting and Accessories

Electrical System Power Centers, Relays & Fuses

Related Articles:

Related Articles: Click Here to See More Carley Automotive Technical Articles

Click Here to See More Carley Automotive Technical Articles