Home, Auto Repair Library, Auto Parts, Accessories, Tools, Manuals & Books, Car BLOG, Links, Index

I've been an internal combustion guy all my life, mainly because there was no other option until recently. Yes, internal combustion engines are capable of making a lot of horsepower and they sound great when the pedal is to the metal. But ICE engines are horribly inefficient, wasting as much as TWO THIRDS of the fuel they burn as waste heat in the exhaust and heat absorbed by the engine’s cooling system.

They also have many parasitic horsepower losses. This includes the energy required to overcome the friction between the piston rings and cylinders, the energy required to drive the numerous valvetrain components, the energy needed to drive an oil pump to lubricate the engine, the energy needed to turn an external mechanical water pump, alternator, A/C compressor and power steering pump (if used).

ICE engines also have a LOT of moving parts. Dozens of major rotating and reciprocating components including pistons, connecting rods, the crankshaft and flywheel, one to four camshafts, dozens of valvetrain components (valves, valve springs, rockers/followers, lifters & pushrods). It all adds up to a LOT of internal friction, wear and wasted energy that could otherwise be used to motivate the vehicle.

What’s more all of these moving parts require plenty of lubrication, as well as regular oil and filter changes to protect the parts. ICE engines also have large and increasingly complex cooling systems, plus exhaust systems that include catalytic converters, oxygen sensors, mufflers, and sometimes turbochargers. Diesel engines also require complicated exhaust treatment components that require even more maintenance.

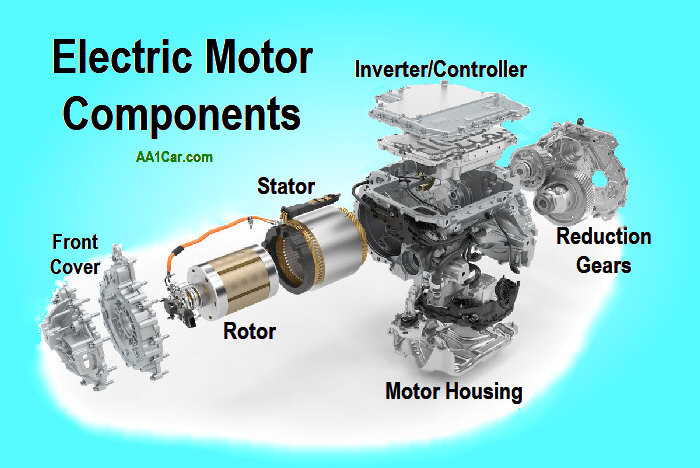

By comparison, electric motors have only ONE moving part (the rotor). They do not require oil changes, filters or maintenance (except maybe a 50k mile change of the motor/inverter coolant). There are no spark plugs to foul or misfire, no bearings, rings or valve guides to wear out, no seals or gaskets to leak, no fuel injectors to clog or die, and no troublesome sensors or emission controls that require testing and occasional replacement.

Electric motors are also about 3X as efficient as ICE engines. Most electric motors use up to 95% or more of the current that is supplied to the motor to produce torque. And you don't have to rev up an electric motor like an ICE engine to generate that torque. It is right there from zero to peak RPM. That’s why they deliver great off-the-line acceleration and instant response. No turbo lag. No hesitation or stumbling when cold. No backfiring or stalling. And no Check Engine Light!

Electric motors can rev like a Formula 1 race car (up to 21,000 RPMs, for example, with KIA’s EV6 GT motor) with no worries about valve float, throwing a connecting rod or running out of oil pressure.

And they are QUIET! The only noise an electric motor typically produces is a slight hum or some gear noise during hard acceleration.

Electric motors do not require a conventional multi-speed transmission (manual or automatic) because of their high torque output and high revving capability. A simple set of reduction gears connected directly to motor multiplies torque for the halfshafts or driveshaft. On some applications, the motor can even be incorporated into the wheel assembly. These differences mean significantly less friction (no 4 to 5% power loss through a conventional transmission and drivetrain), less weight and cost, and higher operating efficiency than any ICE engine and drivetrain.

How about emissions? Zero for electric motors. No carbon dioxide (a proven contributor to global warming and climate change). No carbon monoxide (poisonous and can be deadly). No oxides of nitrogen (NOx is a major cause of urban air pollution and smog). No unburned hydrocarbons, soot or hydrocarbon nanoparticles (a known carcinogen in diesel exhaust and also found in the exhaust of gasoline engines with Direct Fuel Injection). No sulfur dioxide (rotten egg odor from sulfur in gasoline). No evaporative emissions from the fuel system (because there is no fuel system). No crankcase emissions (because there is no crankcase or internal combustion).

It can be argued that although an electric motor by itself is a zero emission engine, the electrical energy needed to charge the battery often comes from coal or natural gas-fired power plants. True, but those emissions are happening anyway to run the electrical grid. Using some of the electricity to charge up the relatively small number of EVs on the road has no impact on overall carbon emissions. And in areas where there are wind farms, solar panels, nuclear reactors or hydroelectric dams, the argument that EVs are just shifting the source of pollution away from the vehicle to a dirty coal-fired power plant does not stand up.

In Iowa, for example, the latest numbers (for 2022) show that Iowa gets 55 percent of its electrical power from wind farms, 33 percent from coal-fired power plants, and nearly 10 percent from natural gas power plants. So at least HALF of the electricity that is used in Iowa to recharge EVs is clean energy.

In Illinois, 54 percent of the power comes from nuclear plants, 30 percent from coal fired-plants, 10 percent from wind farms, and 7 percent from natural gas. So in Illinois, 64 percent of the electricity that is used to charge EVs is clean.

Keep in mind the amount of electricity needed to charge up a typical EV battery is about the same as running an electric clothes drier, which isn't that much.

Because of these advantages, I’m sold on electric motors as the powerplants of the future.

Yes, battery technology still has a LOT of room for improvement. However, each new generation of batteries is getting more efficient and better able to handle ultra fast charging. Battery manufacturing costs are coming down while energy capacity and range continue to increase. Some new battery technologies may eliminate the need for expensive metals such as cobalt, nickel and lithium, while minimizing the environmental impact of mining, refining and recycling EV battery materials.

The availability of EV charging stations is expanding and will grow significantly as the market moves away from ICE vehicles. GM recently announced it will install EV charging stations in many rural areas that currently lack such capabilities. Trying to find one now outside major metro areas or off major highways is like trying to find a needle in a haystack. But that will change.

I currently do not own an electric vehicle. But when the time comes to replace one of my ICE vehicles, I will seriously consider buying an EV depending on the price, range and practicality it offers for everyday driving.

Related Articles:

Related Articles: