Home, Auto Repair Library, Auto Parts, Accessories, Tools, Manuals & Books, Car BLOG, Links, Index

The Basics of Tire Rotation

Copyright AA1Car.com

The reason for rotating the tires every so often is that changing their position on the vehicle helps even out wear to prolong the life of the tires. Rotating the tires also prevents the tires from developing pattern wear problems that may result from turning in the same direction on the same wheel for thousands and thousands of miles.

Most most common recommendation is to rotate the tires every 6000 miles. If you wait too long, you lose the benefits of rotating the tires regularly. Your tires can develop a permanent wear pattern that can create a rough, noisy ride and will reduce the life of your tires.

When you are rotating your tires, inspect each tire for any unusual wear, tread damage, sidewall damage or other problems. Run your hand across the tread. If you feel sharp ridges, one way but not the other, or you feel bumps or humps along either side of the tread or across the middle of the tire, it means the tire has developed a wear pattern that may be the result of wheel misalignment. You should have the wheel alignment checked and corrected as needed to prevent additional tire wear from occurring.

If a tire shows cupped wear, it indicates worn shocks or struts that need replacing.

Heavy shoulder wear on the inside edges of both front tires or both rear tires typically indicates toe-out misalignment and/or too much negative camber.

Heavy shoulder wear on the outside edges of both front or both rear tires is usually a symptom of toe-out misalignment or to much positive camber. Heavy shoulder wear on an inside or outside edge of just one tire is usually the result of too much or tool little camber. The underlying cause may be a weak spring or worn or collapsed control arm bushings.

If your vehicle has a full-sized spare tire, the spare should be included in the rotation to increase the life of all of the tires 20 percent. Including the spare tire in your rotation pattern spreads the wear around to all five tires, not just the four that are on the ground.

On front-wheel drive vehicles, there is some disagreement as to whether or not rotation saves rubber. The back tires on a FWD car can sometimes last 60,000, 70,000 or even 80,000 miles - if rear toe and camber are within specifications and there are no worn or damaged suspension parts. The front tires, however, usually wear out much faster than those on a rear-wheel drive car because they have the added burden of driving the vehicle as well as steering it. Tire life can be as little as 50,000 miles depending on the tread wear rating of the tires and the kind of driving you do. But most quality tires with a tread wear rating of 380 or higher should last upwards of 70,000 miles as long as the wheels are within alignment specifications and there are no worn or damaged steering or suspension parts.

One very important point worth noting is that some FWD cars and minivans have a lot of movement in the rear suspension that can create a heel-and-toe bumpy wear pattern along the inside edges of the rear tires or across the tread. If the tires are not rotated, this pattern will continue to grow until the tires become noticeably noisy and rough. By then it is too late to rotate the tires because the pattern will be too great to wear off in 6000 miles.

Rotating the tires will spread the wear around to all of your tires -- which is probably cheaper than having to replace both front tires or both rear tires before the other tires wear out.

CAUTION: Worn tires with reduced tread depth are more likely to hydroplane and lose traction on wet roads. This increases the risk of skidding and spinning out of control. This is especially true if the tires with the most wear are on the rear axle. Rotating the tires regularly will even out the wear between all four tires and reduce the risk of the rear tires skidding and losing control of your vehicle.

If you are buying two new tires to replace worn front or rear tires, most tire experts recommend installing the new tires on the REAR axle. If the front tires are worn out, move the old rear tires to the front and put the new tires on the back. Putting the new tires in the rear will reduce the tendency to hydroplane and oversteer when driving or braking hard on wet roads. If you mount the new tires on the front and leave the partially worn tires in the rear, you will get better traction with a FWD vehicle but less overall stability and a greater risk of skidding (even with ABS).

Here is something else to keep in mind if your vehicle has a mix of new and worn tires. The normal tire rotation patterns described below apply to tires that have about the same amount of wear (no more than about 2/32 inch difference in tread depth). If your tires have a greater difference in tread wear (more than 2/32 or 1/16 inch difference between the front and rear tires), rotate the tires side-to-side only on the same axle. Do not use a cross pattern (FXR or RXF) as shown below.

On some all-wheel drive cars and fulltime four-wheel drive (4x4 or 4WD) trucks, a significant difference in tread wear between the tires side-to-side or front-to-rear may increase wear in the center differential.

On vehicles with electronic stability control (ESC) systems, a large difference in tread wear side-to-side or front-to-rear may reduce the stability control system's ability to maintain steering control under adverse driving conditions. Tires with different amounts of tread wear may also trigger false ABS or ESC trouble codes. Tire wear reduces the circumference of a worn tire slightly, causing it to turn slightly faster than tires with full tread. This may fool the ABS/ESC system into thinking a tire is losing traction or there is a defective wheel speed sensor. Either way, if a fault code is set, it usually deactivates the ABS/ESC system!

Some FWD cars experience rear toe wear problems more than others due to flex and compliance in the rear suspension bushings. If the tires are NOT rotated often enough, the tread on the rear tires can wear unevenly, often creating a rough sawtooth heel and toe wear pattern that causes a rumbling noise or vibration that may feel like a bad wheel bearing.

Jack, lug wrench (or torque wrench), and FOUR safety stands. The entire vehicle must be raised off the ground to rotate all four tires. NOTE: Make sure your vehicle is parked on a level surface before raising it off the ground.

1. Pop off all the hubcaps, then loosen all the lug nuts half a turn while the wheels are still on the ground.

2. Raise all four wheels off the ground, and position a safety jack under each corner of the vehicle to support it.

3. Now remove each wheel and place it on the ground next to the hub from which it was removed. If your vehicle has a full-sized spare, and you are including the spare in the rotation pattern, take it out of the trunk and lay it on the ground.

4. Choose a rotation pattern (see illustrations) and make sure you use the SAME pattern every time you rotate your tires. Now rotate the tires following the procedure you have chosen.

FWD cars and minivans: Most tire stores recommend rotating the front tires to the rear, and the rear tires to opposite side on the front.

RWD cars and trucks: The most common recommendation is to move the rear tires to the front (same side) and rotate the front tires to the opposite side on the rear.

AWD and 4WD cars and trucks: For these kind of vehicles, the usually recommendation is to rotate both rear tires to the opposite side in the front, and both front tires to the opposite side in the rear (X-cross pattern). The main advantage with this pattern (which can be used on ANY vehicle including FWD and RWD) is that it makes all four tires rotate in an opposite direction each time the tires are rotated. With the previous rotation patterns, the tires only switch the direction they rotate once every other rotation. Consequently, if your vehicle has a tendency to develop an abnormal tire wear pattern, using the X-cross pattern to reverse the direction the tires turn will help offset the wear and extend tire life.

Directional tires: The tread pattern on many high performance tires are designed for optimum traction in one direction only. Directional tires have arrows on the sidewall showing the way the are supposed to rotate all the time. These tires should only be rotated front to rear, never side-to-side or crosswise, and then only if the front and rear tires are the same size.

If your vehicle has STAGGERED tire sizes (Different tires sizes front and rear): Due to the difference in diameter, such tires can only be rotated right to left (side-to-side) not front to rear or crosswise. And if the tires are also high performance directional tires of different diameters, you cannot rotate them at all!

If your vehicle has a fullsize spare tire (which few do anymore), you can include the spare tire in the rotation. Use this scheme: Mount the spare tire on the left front (drivers's side) hub. Put the right rear (passenger's side) tire in the trunk. The right front tire moves to the rear (same side), and the left rear tires crosses over to the right front.

WARNING: Do NOT include a compact, space saving or Temporary spare tire in your rotation pattern. Why? Because the tire diameter is smaller than the other tires on your vehicle. This will upset the wheel speed sensor readings, which in turn affects the operation of the antilock-braking and stability control systems. On an All-Wheel Drive (AWD) vehicle, it can also upset the operation of the AWD system. What's more, most compact and temporary spares are NOT designed for extended driving (50 miles or less) or high speed driving (vehicle speed should not exceed 55 mph max).

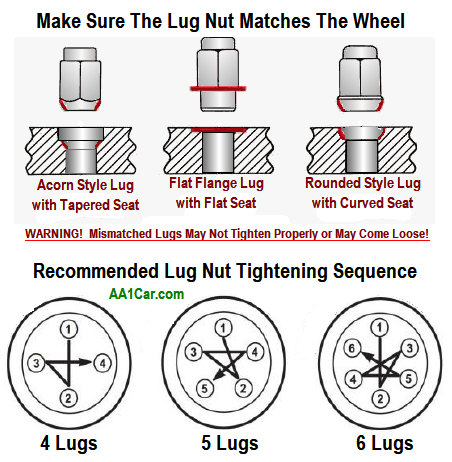

5. Finger tighten all the lug nuts, then lower the vehicle to the ground and finish tightening all the lug nuts with a torque wrench. Tighten the lug nuts in a star pattern to the recommended specifications (Look up the lug nut torque specs for your vehicle!). Typical lug nut torque specs are around 80 to 90 ft. lbs. for most small to medium sized passenger cars with 4 and 5 lug wheels, 100 ft.lbs. for large cars, 110 to 150 ft. lbs for fullsize pickup trucks and SUVs with 6 to 8 lug wheels).

6. Replace the hubcaps, and put the jack and lug wrench back in the trunk or storage compartment.

7. Make a note of the mileage at which you rotated the tires in your maintenance record for future reference.

Proper torque on lug nuts is very important for three reasons. One is to keep the lug nuts from loosening up and the wheel coming loose, another is to prevent distortion of the brake rotor behind the wheel, and a third is to prevent broken studs. A torque wrench should be used for final tightening of the lug nuts, and the nuts should always be torqued to the recommended specifications. An impact wrench can be used to tighten lug nuts but only if used with a TORQUE STICK that limits peak torque (see below).

CAUTION: Torque specifications for lug nuts are always for CLEANand DRY studs and lug nuts. That means no oil, no grease, no anti-seize and no lubricants of any kind. Any of these products will reduce the friction between the threads. This may seem like a good thing to prevent rust and frozen lug nuts, but the reduction in friction means a much higher percentage of the applied torque (up to 25% or more) will go toward loading the lug nuts. The end result may be brake rotor distortion or broken studs!

Wheel studs should be cleaned with a wire brush to remove rust and dirt BEFORE the wheels are mounted. If the lug nuts are heavily rusted or have damaged threads and won't turn easily on the studs, replace the lug nuts. The same goes for any wheel studs with damaged or badly corroded threads. And remember to mount the wheels DRY with nothing on the threads.

DO NOT use an impact wrench to final tighten lug nuts unless you are using a torque stick to limit the amount of peak torque applied to the lug nut. The applied torque from an impact wrench is too uneven and inconsistent lugs to lug, so you have to use a torque stick to even out and limit peak torque, otherwise you risk overtightening some lug nuts and undertightening others. Uneven torque can distort the brake rotor, which can lead to uneven rotor wear and brake pedal pulsation.

More Tire Related Articles:

More Tire Related Articles: Click Here to See More Carley Automotive Technical Articles

Click Here to See More Carley Automotive Technical Articles