Home, Automotive Repair Library, Auto Parts, Accessories, Tools & Equipment, Manuals & Books, Car BLOG, Links, Index

The Basics of Tire Pressure Monitor Systems (TPMS)

by Larry Carley copyright AA1Car.com

Tire Inflation Pressure Monitor Systems (TPMS) are now required on all new vehicles. Low tires are potentially dangerous, especially if a vehicle is heavily loaded and traveling at highway speeds during hot weather. A low tire under these conditions is a blowout waiting to happen. The inflation pressure of the tires should be checked regularly, but many motorist do not check their tires. That is why Tire Pressure Monitor Systems have come into use.

Tires are designed to operate within a certain pressure range. The recommended inflation pressure can usually be found in the vehicle owner's manual and on a decal that may be located in the glove box or door jam. The recommended inflation pressure is designed to give the best combination of ride comfort, load carrying capacity and rolling resistance.

NOTE: The maximum cold inflation pressure on the sidewall of a tire is NOT the recommended inflation pressure. It is a maximum limit for the tire only. The recommended inflation pressure for most passenger car tires is 32 to 34 psi (cold).

Increasing the tire inflation pressure reduces rolling resistance (which helps fuel economy). It also increases the load carrying capacity of the tire. But it also increases ride harshness. The maximum inflation pressure (which can be found on the sidewall of the tire) should never be exceeded because too much pressure may overstress the tire and increase the risk of tire failure.

Decreasing the inflation pressure improves ride quality by making the tire softer. Under certain circumstances this may help improve traction a bit. But lowering the pressure also reduces the tire's ability to carry weight and increases rolling resistance (which hurts fuel economy).

A low tire also wears faster. Why? Because increased rolling resistance and flexing in the tread scrubs away the tread. As the miles add up, so does the wear and eventually the tread is down to the wear bars. Once the wear bars are flush with the surface of the tread, the tire needs to be replaced.

The increased friction in the tread and the sidewall that results from underinflation also generates heat. All tires are engineered to operate within a certain temperature range, which you'll find on the side of the tire (A, B or C, with A being the best). When a tire is underinflated, it runs much hotter than normal. This may or may not create a potentially dangerous situation depending on how low the tire is, how fast the vehicle is driving, how heavily it is loaded and the ambient temperature. The lower tire, the more heavily loaded the vehicle, the faster is is traveling and the hotter the weather, the greater the risk of a blowout.

A blowout can have deadly consequences because it often causes the vehicle to lose control. If the blowout occurs on a vehicle like a truck or SUV with a high center of gravity, it greatly increases the risk of a rollover.

Tire pressure needs to be checked regularly (every couple of weeks) because all tires lose pressure over. Where does the air go? It seeps out through microscopic pores in the tires, tiny leaks in the bead seal, and even through porosity leaks in alloy wheels. Some tires tend to seep more than others, and if a tire has a tiny puncture or a cut, it can lose a lot of air in a hurry.

You can't always judge a tire's inflation pressure by appearances alone. By the time a low profile radial tire appears to be low, it may be 10 to 15 psi underinflated.

According to a recent survey by the Car Care Council, 54 percent (that's over half!) of vehicles inspected during National Car Care Month were found to have improperly inflated tires. Most were low, but some were dangerously overinflated, too.

The Government Accounting Office estimates that probably 250 lives a year might be saved by reducing the number of fatal accidents that are attributed to underinflated tires. To read this government report, Click Here.

The point here is that many motorists rarely check the inflation pressure in their tires, and if they do they may not do it correctly. Tire pressures must be checked when the tires are cold because driving generates friction and heat that increases the pressure inside the tires. The outside temperature also affects tire pressure (pressure drops about 1 PSI for every 10 degrees F).

Checking inflation pressure also requires an accurate tire gauge. We've seen cheap tire gauges that are off as much as 6 psi right out of the package. The gauges on many gas station tire inflation machines are even less accurate.

If you see this TPMS icon illuminated, it means your vehicle has a low tire. STOP, and check the inflation pressure in your tires. This warning light will come on if tire pressure in any of your tires falls more than 25% below the recommended inflation pressure (refer to your owners manual, or the tire inflation decal in the glovebox, driver door pillar or gas tank filler cap lid for tire inflation pressure recommendations).

The TPMS warning light should come on for about one second when the ignition key is first turned on for a bulb check. It should then go out if all of the tires are properly inflated. If it does not go out, or it comes on while driving, you have a low tire.

NOTE: If the TPMS warning light is flashing, it indicates a fault has been detected in the TPMS system that will require further diagnosis. Common faults include a bad tire pressure sensor, a defective keyless entry receiver module, a fault in the TPMS or body control module (BCM), or wiring problems in the keyless entry/TPMS/BCM circuit.

This brings us to tire inflation monitoring systems. If motorists won't check their tires, vehicles can be equipped with their own tire pressure monitoring systems (TPMS). For model year 2008 and beyond, National Highway Traffic Safety Administration (NHTSA) regulations require all new cars and light trucks to be equipped with a tire pressure monitoring system. The TPMS system must warn the driver if the pressure inside any tire on the vehicle is 25 percent or more under the recommended inflation pressure.

Many late model cars and SUVs are factory-equipped with TPMS. Run-flat tires with a TPMS system have been used since 1989 on the Chevrolet Corvette. Other older run-flat/TPMS applications include the Plymouth Prowler, BMW Z8, Mercedes-Benz SL55 AMG, 2002 Infinity Q45 and 2004 all-wheel drive Toyota Sienna.

TPMS can also be found on the following vehicles that have conventional tires: 2003 Ford Explorer, Mountaineer, and Lincoln Navigator, 2000 Cadillac Seville & DeVille, 2003 Chrysler 300M, Town & Country minivan and Dodge Viper, and Jeep Grand Cherokee and Liberty. Import applications include 2001 and up Audi A8 and Quattro, 2001 and up BMW M3, 2003 and up BMW 3-Series, &-series and Z4 roadster, 2000 and up Nissan Quest minivan, 2003 and up Nissan 350Z and Murano SUV, and 2004 Toyota Sienna. For model year 2008 and newer vehicles, all passenger cars and light trucks that are sold in the U.S. must be equipped with TPMS.

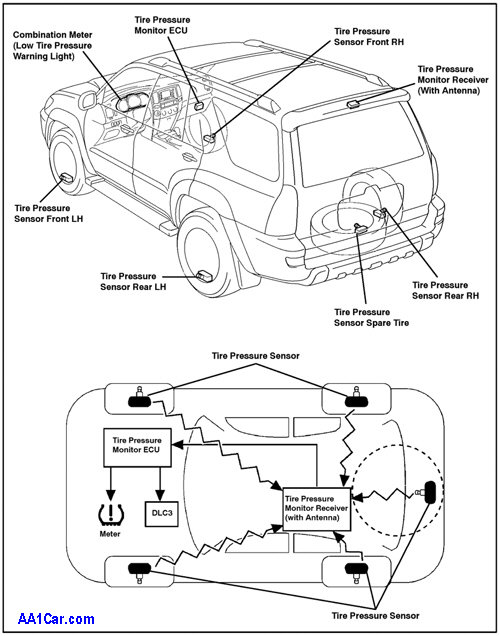

There are essentially two basic ways to monitor tire pressure electronically. One is the direct method. A small pressure sensor is located inside each wheel. The sensor has a built-in transponder that broadcasts a radio signal to an external module. The module identifies the signal from each wheel and keeps an eye on pressure. If pressure drops below a predetermined threshold, the module turns on a light or displays a message to warn the driver.

The pressure sensors may be mounted in the drop center inside the wheel, or on the end of the valve stem inside the wheel. Stem mounted pressure sensors use the valve stem as the antenna, so don't replace the standard valve caps with anything else. Sensors attached to the rim drop center are typically held in place by a long steel strap that wraps all the way around the wheel. The pressure sensors are very accurate (usually within 2 lbs. or less).

The other method of monitoring tire pressure does not require any additional hardware inside or outside the wheel. It is the "indirect" method. This approach makes use of the existing wheel speed sensors in the antilock brake (ABS) system. By modifying the ABS operating software, the ABS system learns the average speed at which each wheel rotates when traveling straight at a constant velocity, and detects low tires by comparing relative wheel speeds. The auto makers like this approach because it is a simple, cost-effective way to monitor tire pressure. But it has some limitations.

On most North American indirect TPMS systems (1999 to 2003 model year applications), the systems cannot detect a low tire if two tires on the same axle are low, or if all four tires are low by an equal amount. But it can detect one or more low tire if the rest are at or near the recommended inflation pressure.

Here's how the indirect ABS-based TPMS works. If a tire loses air, the diameter of the tire shrinks slightly causing it to turn at a slightly faster rate than the others. But on most applications, a tire has to loose anywhere from 8 to 14 pounds of air pressure before there's enough of a difference in diameter to be detected by the wheel speed sensors. It depends on the type of tires, tire diameter and aspect ratio, and the sensitivity of the ABS system.

Low profile tires with short stiff sidewalls change diameter less than tires with taller aspect ratios and more compliant sidewalls. Consequently, a loss of 10 psi in a low profile tire may only change the diameter of the tire less than 1 mm (0.040 inches). Most ABS systems cannot detect changes smaller than 1 mm. For this reason, indirect ABS-based tire pressure monitoring systems are not as sensitive as direct TPMS systems that have a pressure sensor inside each wheel.

ABS-based systems must also relearn the rotational "signature" of each tire when tires are replaced, repaired or rotated. This requires the driver to push a reset button on the dash or to follow a menu on the driver information display. It's also essential that the tires all be properly inflated before the recalibration procedure takes place -- otherwise the module won't recalibrate correctly and may not detect a low tire.

Some vehicles that currently have indirect ABS-based TPMS include 2001 to 2003 Ford Windstar, 1997-2002 Buick Park Avenue, 1999-2003 Buick Century & Regal, 2002-2003 Buick LeSabre, 2003 Buick Rendezvous & Aztek, 2000-2003 Chevy Impala & Monte Carlo, 1999-2002 Chevy Alero, 1999-2002 Pontiac Grand Am, 1997 - 2003 Pontiac Grand Prix, 2000 - 2003 Pontiac Bonneville, and 2001-2003 Oldsmobile Aurora.

Indirect tire pressure monitoring systems have fallen out of favor because direct systems are more accurate and can display exact tire pressure readings for each tire. Consequently, virtually all auto makers are now using direct TPMS systems on late model vehicles.

As for the direct TPMS systems, they have their own technical issues as well. One is battery life. The pressure sensor inside each wheel contains a small battery to power the sensor and transponder. Most are long-life lithium 3-volt batteries that last five to 10 years. Eventually, the batteries will go dead. Battery life depends on the sampling frequency of the sensor (how often it broadcasts a signal), vehicle use (how often it is driven), and ambient temperatures (hot weather tends to shorten battery life). Average battery life for most TPMS sensors is around 7 years.

On most applications, the battery is sealed inside the TPMS sensor and cannot be replaced separately. If a battery has gone dead, therefore, you have to replace the sensor. Most tire experts say it is a good idea to replace ALL of the TPMS sensors if one of the batteries has died and the sensors are more than five years old. The reason? Battery life will be more or less equal among all the sensors, so if one has died the other batteries are probably near the end of their service life too.

The best time to replace TPMS sensors is when you are buying new tires. Most tires will go 60,000 to 80,000 miles or more with normal driving, proper inflation and correct wheel alignment and balance. By the time you need new tires, the batteries inside your TPMS sensors have probably used up most of their reserve charge. It is very unlikely they will last another set of tires.

Some TPMS service tools can actually tell you how much charge is left inside the TMPS sensor batteries. Not all vehicles provide this data, but many can. The tool will query each sensor and display a percentage of charge left in the battery, or show a LOW indication if the remaining charge left in a battery is down to 10 or 15 percent. That would translate into maybe 6 to 9 months of remaining service life before the sensor goes dead and has to be replaced.

Another issue with direct TPMS systems is keeping track of which wheel is which. Rotating the tires obviously changes the location of each transponder. So the system must be reset so the control module can relearn the position of each transponder. This may require the driver to push a reset button on the dash or to follow a menu on the driver information display.

On some applications (notably Toyota), each TPMS sensor has its own unique factory code, and must be programmed for each wheel location using a scan tool. With most other applications, a special learning procedure must be performed to teach the system the location of each sensor. Relearn procedures vary quite a bit from one vehicle to the next.

On the Corvette and Cadillac applications, the transponders in each wheel must be reset if the wheels are rotated to another position on the vehicle. This can be done by placing a J-41760 magnet over the valve stem or by using a Tech 2 or equivalent scan tool.

Magnet method: With the key on, engine off, press both the lock and unlock buttons on the key fob. A horn chirp within 10 seconds indicates the TPMS receiver is in the programming mode. Place the magnet over the left front valve stem until the horn chirps. This forces the LF pressure sensor to transmit its code to the main module. Repeat the same procedure for the right front, right rear and left rear sensors in this order. Verify all four pressure readings are displayed on the driver information center.

Scan tool method: If no sensors are being replaced, you can use your scan tool to reprogram the new wheel locations. Just follow the menu prompts when you come to the "TPM Reprogramming Procedure."

On Cadillacs, if the instrument panel cluster is disconnected or replaced, it must be reprogrammed with a scan tool to enable the tire pressure monitoring function.

Also, if the battery is disconnected or drops below a certain voltage on a Corvette or Cadillac with the tire pressure monitoring system, the vehicle may forget the location of the tire pressure sensors and have to be reset. This may also set diagnostic trouble codes for all four pressure sensors.

On Corvette and Cadillac applications, the receiver for the wheel pressure transponder signals is the keyless entry system module. If there's a problem with this module, it will obviously affect both the ability to unlock the doors with the remove key fob and the ability to monitor tire pressures.

On most Asian import applications, each sensor has a code that is programmed into the TPMS control module at the factory. If one or more of these original equipment sensors is later replaced with an OEM or aftermarket sensor, the new sensor code(s) must be manually programmed into the TPMS system using a scan tool. That means a trip to the dealer if you do not have a factory scan tool or an aftermarket scan tool with the appropriate software in your shop. Vehicles that currently require this kind of reprogramming include most Hyundai, Infiniti, Kia, Lexus, Mitsubishi, Nissan, Subaru, Suzuki and Toyota models.

Removing a wheel from a vehicle when doing brake or suspension repairs does not require any special procedures on TPMS equipped vehicles. Just remount the wheel in the same location as before when you have finished the repairs. But if you are rotating tires, or moving a wheel from one location to another (as when troubleshooting a steering pull or vibration problem), the TPMS system will have to be taught the new position of each sensor. This will require a scan tool or a special TPMS test/relearn tool.

When removing more than one wheel at a time from a TPMS-equipped vehicle, use a piece of chalk to mark each wheel's position (RF, LF, RR, LR). That way, you won't forget which wheel went where and accidentally mount the wheels in the wrong locations.

Aftermarket TPMS testers are available from a number of sources including Bartec, OTC, Schrader and others). Prices range from under $500 to $1500 or more depending on the model and its capabilities. Most of these testers cover a wide range of makes and models (import and domestic), but some may be limited to specific models or types of sensors (such as sensors that operate in continuous mode or modulated mode only).

Aftermarket TPMS testers are available from a number of sources including Bartec, OTC, Schrader and others). Prices range from under $500 to $1500 or more depending on the model and its capabilities. Most of these testers cover a wide range of makes and models (import and domestic), but some may be limited to specific models or types of sensors (such as sensors that operate in continuous mode or modulated mode only).

The tester communicates electronically with the sensors and TPMS system. The unit typically activates the pressure sensors so they will broadcast a signal. The unit then programs the TPMS module or receiver in the vehicle so it will recognize which sensor is which (RF, LF, RR, LR). The tool can also be used to verify the operation of each individual sensor and to troubleshoot TPMS faults. Many of these tools have a USB port that allows the tool's software to be updated as needed, and to download information from the tool to a PC for printing or recording.

On many Toyotas, there is a TPMS reset button inside the glove box. To reset the system, turn the ignition ON, then press and hold the reset button for three seconds. When the TPMS warning light blinks three times, the system is reset. Wait at least five seconds before turning the ignition OFF so the system will recognize the new tire pressure readings.

On a Toyota Land Cruiser, there is a Main/2nd switch that allows the vehicle owner to use two different sets of wheels and tires (on-road and off-road). The switch tells the TPMS system which set of sensors to look at using the ID numbers that were programmed in at the factory.

On a 2006 Volkswagen Jetta, the TPMS system won't reset unless the car has been parked for at least 20 minutes. The car must then be driven at 16 mph or faster for at least seven minutes for the system to reset and relearn the new pressure settings. Only then will the TPMS warning light go out.

DO NOT USE TIRE SEALER WITH TPMS SENSORS

WARNINGIf you have a flat tire on a vehicle with TPMS sensors in the wheels, do NOT attempt to fix the flat by using an aerosol tire inflator/sealer product. The sealer may gum up the TPMS sensor inside the wheel and prevent it from reading normally. Most aerosol inflator/sealer products have a warning on the product label stating they should NOT be used in wheels that contain TPMS sensors. Inflator/sealer products are safe to use, however, in tires on vehicles that have an indirect TPMS monitoring system.

On vehicles equipped with indirect ABS-based tire pressure monitoring systems, no special service precautions should be necessary. Just remember to reset the system if the tires have been replaced or rotated. Also, don't forget to check each tire to make sure it is at the recommended pressure BEFORE the system is reset.

If there is a fault in the system, it will usually be in a wheel speed sensor circuit (bad wiring, loose or corroded connector or a faulty sensor). This may also disable he ABS system until the fault is repaired.

Note: Replacing the original tires and/or wheels with different sized aftermarket wheels may upset the calibration and operation of the ABS system as well as the TPMS system.

On vehicles that have direct TPMS with a sensor and transponder inside each wheel, care must be used when dismounting and mounting tires on their rims. On a Corvette with Goodyear EMT/run-flat tires, the sidewalls are very stiff. This makes the tires difficult to remove and mount. Care must be used when breaking the bead and removing the tire on a tire machine so the sensor is not damaged. On applications where the sensor is clamped to the rim, it will be located in the wheel drop center 180 degrees across from the valve stem hole. When dismounting the tire, the tire must not be forced down over the sensor because doing so may damage the sensor and/or the bead.

On applications where the TPMS sensor is on the valve stem, be careful when dismounting/mounting tires so the tire bead or tire machine roller does not damage the sensor. Position the bead breaker 180 degrees across the wheel from where the valve stem is located.

If you are buying new tires for your vehicle, the tire store will likely recommend replacing the valve stems and TPMS sensors. This may seem like an expensive and unnecessary service, but it is for your own safety. By the time your vehicle needs tires, the batteries inside the TPMS sensors may be reaching the end of their service life. So it makes sense to change the sensors and valve stems when the tires are replaced.

If you have a bad TPMS sensor, it will have to be replaced with a new one. There is no way to repair a TPMS sensor.

Because of the great variety in TPMS sensor designs and configurations, it is important to find the correct replacement sensor for your vehicle. Original equipment TPMS sensors from a new car dealer can be very expensive, so there are now numerous aftermarket sources for these sensors. Most auto parts stores and tire dealers carry sensors to fit your vehicle.

The newest trend in replacement TPMS sensors is "universal" sensors. A single sensor can be programmed to work on a variety of different applications. This simplifies inventory for parts stores and tire dealers by reducing the number of different sensors that are needed to cover all the various makes and models of vehicles that are equipped with TPMS.

Click Here for information about Bartec and Schrader's EZ-Sensor.

Click Here for information about VDO's Redi-Sensor universal TPMS replacement sensor.

INSTALLING AN AFTERMARKET TIRE PRESSURE MONITOR

One way to upgrade driving safety is to install an aftermarket tire pressure monitoring system. The cheapest type (under $15) are simple spring-loaded "safety caps" that fit on the existing valve stems. The safety caps have a window that show a color indicator inside. Green means the tires are okay (30 to 32 psi), yellow shows if pressure drops four pounds, and red shows if pressure drops 10 or more pounds. The only drawback with this system is that it requires the driver to visually inspect the tires. There is no warning light or message inside the vehicle -- which means if a tire loses pressure while driving you won't know it until it goes flat.

There are also aftermarket direct TPMS systems that work similar to the factory systems. A pressure sensor/transponder is mounted inside each wheel (usually on the valve stem) and feed signals to a module that is mounted on or under the instrument panel. These systems typically sell for around $200 plus installation. These are not really a DIY product because the tires have to be dismounted to install the pressure sensors inside the wheels. Consequently, you can make the labor for dismounting/mounting the tires, installing the sensors, rebalancing the tires (if necessary), and installing the module/display head inside the vehicle.

More Tire Articles:

More Tire Articles: Click Here to See More Carley Automotive Technical Articles

Click Here to See More Carley Automotive Technical Articles