Home,

Auto Repair Library, Auto Parts, Accessories, Tools, Manuals & Books, Car BLOG, Links, Index

Repairing Cracks

in Cast Iron Cylinder Heads and Engine Blocks

Copyright AA1Car.com

Adapted from an article written by Larry Carley for Engine Builder magazine

Crack repair has become one of today's hottest topics because good rebuildable cylinder heads for many late model engines are very expensive and hard to find. So many engine rebuilders are now repairing heads they would have thrown out only a few years ago as unsalvageable.

There have always been options for repairing cracks in cast iron. Pinning and furnace welding are both viable options that have long been used to repair cracks and other kinds of damage. But pinning has its limitations, and furnace welding is not something a novice can learn overnight.

Crack repair also involves a certain amount of risk. That is why most of the crack repair activity in the past was limited to high cost heavy-duty diesel heads, antique heads or other jobs that justified the time, effort and risk. But due to the high cost of many late model heads and blocks, crack repair may be a cost-effective alternative to buying a new or used casting to replace a cracked head or block.

OPTIONS FOR REPAIRING CRACKS

Cracks in aluminum heads and blocks are relatively easy to repair by TIG welding, but cast iron is much more difficult to weld. That is why pinning has long been the most popular method of repairing small cracks in cast iron blocks and heads. Pinning can repair about 80 percent of all cracks but it can't fix every kind of crack. A lot depends on the location of the crack and its severity. Tapered pins with sealer work well on most applications. Welding, on the other hand, restores integrity and allows you to fill cracks and holes. You can even change the shape of the combustion chamber or a port by adding metal.

Various types of pins can be used to repair cracks

and holes in cast iron cylinder heads.

PINNING TO FIX CRACKED CYLINDER HEADS

Pinning is the most commonly used technique for repairing cracks in cast iron head, blocks and manifolds because it is fast, reliable and cheap. Pins can also be used to repair cracks in aluminum heads and blocks, too, although TIG welding is often the preferred repair method for aluminum. Pinning is a relatively easy technique to learn and use, does not require much in the way of tools except a drill, guide fixture and tap, and uses no heat.

Overlapping pins seal the crack.

Essentially, pinning involves drilling holes in a crack, installing overlapping pins to fill the crack, then peening over the pins to seal and blend the surface.

There are two basic types of pins: straight and tapered. Each type has its advantages and may work better in certain situations than the other.

Tapered pins pull themselves into a crack as they are tightened to provide a tight seal along the entire length of the pin. This occurs because the threads on both the tapered pin and hole have an interference fit. Sealer really is not necessary, but is often used for added insurance. The holes for tapered pins must be carefully hand tapped and the pins hand tightened for a tight seal.

Straight pins are faster to install because an ordinary tap and power drill can be used to install them. Straight pins are designed to twist off when tightened, eliminating the need to cut or grind the heads off (as is necessary with tapered pins). Straight pins also have an interference fit over their entire length, and a tapered shoulder that crushes into the surface. This eliminates a thread line on the surface enabling the surface to be machined. This type of straight pin can also eliminate the need for installing valve seat inserts in cast iron heads.

Various types and sizes of crack repair pins and plugs.

Ordinary tapered and straight pins cannot handle certain kinds of cracks, such as those along an outside edge or corner that require support to hold the sides of the crack together. The same goes for cracks in an area of a casting that would open up or pull apart when the casting is under load or gets hot. For these types of crack repairs, locking devices and/or pins with a self-gripping ability can provide the required reinforcement and strength. "Castmaster" pins (manufactured by Lock-N-Stitch) have a unique "spiral hook" or "reverse pitch" thread pattern that grips both sides of a crack when the top shoulder of the pin bottoms against the metal. This type of pin can actually hold a crack together rather than just fill it, and may be used to repair cracks that cannot be fixed with ordinary tapered or straight pins.

Another crack that is difficult to repair by pinning is any crack that occurs in very thin (less than 1/8 inch wall thickness) area of a casting. Pins will not hold unless there is enough metal to grip and support the threads.

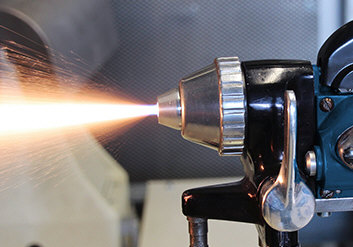

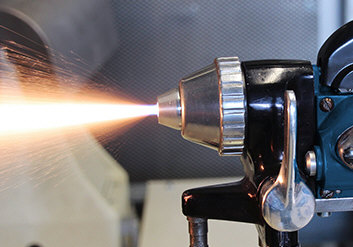

Furnace welding uses a torch, an oven and lots of heat.

FURNACE WELDING CAST IRON

Cracks in cast iron can be repaired by hot welding (furnace welding), but it is a technique that takes skill and lots of practice. It also requires preheating the casting before it is welded, and lots of heat (preheat to 1200 to 1400 degrees F. in n oven). The casting must also be slow cooled seven to eight hours after welding to prevent it from recracking.

Successful crack repair by furnace welding (hot welding) requires careful preparation of the crack beforehand, and careful heat management. You cannot just heat up a head with a weed burner. The right way is to preheat the head in an enclosed furnace or oven so the heat comes up through the head from the bottom. You have to keep the head insulated with a blanket and prevent any drafts while welding it otherwise you will get cracking and porosity in the weld. The head then be slow-cooled afterwards.

When the head preheat temperature has stabilized (it takes about an hour), a "neutral flame" oxyacetylene torch with slightly more acetylene than oxygen is used to melt the cast iron (which melts at 2400 to 2600 degrees F). Cast iron filler rod and borax flux and then used to fill the crack. The trick is to keep the weld clean by adding a little flux so the impurities will rise to the top. The impurities can then be floated out of the repair area with the torch.

If a valve seat is being furnace welded, one trick is to fill the hole with a graphite plug, then weld up around it. The puddle will be about half an inch deep and maybe two inches in diameter. It takes a lot of heat to do this, about 5000 degrees.

After the crack has been filled comes a long, slow cool down. If cast iron cools too quickly, one of two things can happen. The surrounding metal can shrink away from the weld causing new cracks to open, and/or the carbon in the iron can turn to carbide making the metal too hard and brittle to machine. The casting must therefore be cooled very slowly to prevent these undesirable metallurgical changes.

Wrap the head in an insulating blanket and keep it in a hot box so it will cool at a rate of no more than 100 to 200 degrees per hour. The cool down period can take up to eight hours. After the head has cooled, it can be cleaned to remove the scale, then rough machined and submersion pressure tested in hot water at 100 psi to check for leaks.

If a cast iron head has integral valve seats, replacing the exhaust valve seats after furnace welding is recommended because the high temperatures of the process can destroy the induction hardening of the seats.

SPRAY WELDING CAST IRON

Another alternative for repairing cracks in cast iron heads and blocks is powder welding (also called flame spray welding). The basic technique has been around for many years but has been improved in recent years with new spray welding equipment. It can make a strong a repair similar to hot welding but with much less heat. You still have to preheat and postheat the head to relieve stress that could cause it to recrack. But with this technique, there is less risk of warping or distorting the head from excessive heat.

Flame-spray welding requires a special oxyacetylene torch with a trigger-operated hopper that feeds nickel alloy powder into the flame. When the powder is exposed to the flame, it melts and fuses to the sides of the crack to fill the repair area. The process requires preheating the head to about 700 degrees, and post-heating the head after welding to relieve stress.

The nickel alloy powder used for flame spray welding provides a hardness of 18 to 22 Rc. Harder alloys are available for spray welding valve seats, camshafts and crankshafts.

As with any repair process, there is always a risk of recracking whether a casting has been repaired by TIG welding, furnace welding, spray welding or pinning. Cracks in the valve seat area may reopen if a new valve seat is pressed in with too much interference fit. Welded areas on cast iron may be harder than the base metal, making the casting more difficult to machine.

TROUBLESHOOTING FLAME-SPRAY PROBLEMS

If you are having trouble achieving good results with flame-spray welding, here are some hints that may improve your success:

- If the nickel powder just lays there or stacks up instead of wetting out when starting a weld, the work is too cold. The chamfer must be a dull cherry red, or about 1300 to 1400 degrees F. Trying to force the base metal up to temperature by heating it though a thick .020 inch or greater layer of unfused powder will likely burn the flux out of the powder.

- If the nickel powder boils up when starting a weld and you get a volcanic like reaction when the initial burst of powder is sprayed into the chamfer, the work is too hot. Back off the torch, allow the area to cool to a dull cherry red color, then hold the tip of the blue cone in the flame about 1/8 to 1/2-inch from the deposit and add fresh powder in short bursts. This should add enough new flux to wet out the powder properly. If this does not work, stop, scrape the chamfer clean and start over.

- If too much powder is applied during the initial spray, it won't wet out. When unfused powder builds up to .020 inch or thicker, it acts like an insulator between the flame and base metal. Stop, scrape away the unfused powder, and start over.

- Improper flame angle can also cause the powder to ball up and not wet out. If the flame angle is less than 75 degrees, powder can blow ahead of the puddle and stick to the chamfers. When unfused powder stacks up to about .020 in. or thicker, it will not wet out properly. Trying to force it out with the torch will create porosity and hardness problems. Stop, scrape or brush away the unfused powder, hold the torch at the proper angle and start welding again.

- Porosity and hardness problems in the weld can be caused by surface contamination adjacent to the "V" chamfer. On some castings, manifolds in particular, the surface may contain a lot of "burned" iron. This should be ground away leaving sound, clean metal at least 3.8 to 1/2 inch on either side of the "V" chamfer. Rusty, dirty or burned metal will generally pop and crack when a flame is applied to it.

BRAZE WELDING CRACKS IN CAST IRON HEADS

Braze welding is yet another option for repairing cast iron. It works great on applications such as damaged bolt holes and even cracks in head ports because it is a simpler process. Braze welding can be done at 800 to 900 degrees, which means the casting only heats up to about 400 to 500 degrees and does not distort or melt. It works well for repairing cracks on the tops of thinwall cylinder heads, such as Ford 2.9L heads, and can even be used to repair small cracks in exhaust ports.

Related Articles:

Related Articles:

How to Weld Aluminum

Related Links:

Crack Repairs Methods Explained by Larry Carley

Click Here to See More Carley Automotive Technical Articles

Click Here to See More Carley Automotive Technical Articles

Be sure to visit our other websites:

OBD2HELP

Random-Misfire

ScanToolHelp

TROUBLE-CODES

Related Articles:

Related Articles: