Home, Library, Auto Parts, Accessories, Tools & Eqpt, Books, Car BLOG, Links, Index

What Is Engine Displacement?

by Larry Carley copyright AA1Car.com

by Larry Carley copyright AA1Car.com

When talking about engines, the size of the engine or its "displacement" is often mentioned. What is displacement? It is the volume of air that the engine consumes or pumps through itself every two revolutions. Why two revolutions of the crank? Because it takes two revolutions of the crankshaft to complete the 4-stroke combustion cycle for all of the engine's cylinders. This applies to all four-stroke engines (fours, straight sixes, V6s, V8s, V10s, V12s and V16s).

Engine displacement is typically stated as either "Cubic Inches of Displacement" (CID) or in Liters.

Auto manufacturers will typically round off engine displacement in their promotional literature to the nearest cubic inch or two-decimal liter value. For example, a late model 5.7L Dodge Hemi engine actually displaces 5654 cubic centimeters (cc) or 345 CID. Another example would be a Corvette 6.2L engine that actually displaces 6162 cc or 376 CID.

1.0L = 61.0 CID

1.5L = 91.5 CID

2.0L = 122.0 CID

2.5L = 152.6 CID

3.0L = 183.1 CID

3.5L = 213.6 CID

4.0L = 244.1 CID

4.5L = 274.6 CID

5.0L = 305.1 CID

5.5L = 335.6 CID

6.0L = 366.1 CID

6.5L = 396.6 CID

7.0L = 427.2 CID

7.5L = 457.7 CID

8.0L = 488.2 CID

100 CID = 1.6L

150 CID = 2.5L

200 CID = 3.3L

250 CID = 4.1L

300 CID = 4.9L

350 CID = 5.7L

400 CID = 6.6L

450 CID = 7.4L

Engine displacement is the volume of each cylinder times the number of cylinders.

The volume of each cylinder is determined by the "bore" (width) of the cylinder, and the "stroke" (the distance the piston travels up and down the cylinder). The distance traveled by the piston is determined by the "throw" or offset of each connecting rod journal on the crankshaft. If the crank journal offset is 4 inches from the dead center of the crank, the piston will travel up and down four inches every revolution of the crankshaft.

The basic formula is:

Engine Displacement = 0.7854 x (bore diameter x bore diameter) x stroke x number of cylinders

Basically you calculate the volume of each cylinder, then multiply by the number of cylinders.

Bore and stroke dimensions can be measured in inches or millimeters, then you do the math to determine the number of cubic inches, cubic centimeters or liters. Or, use a conversion table to convert from liters to cubic inches or vice versa.

Bore width or diameter can be measured with a caliper, bore gauge, tape measure or ruler (the caliper or bore gauge will be a lot more accurate than a tape measure or ruler!).

Stroke can be measured by turning the crankshaft until a piston is at Top Dead Center (TDC), which is as high as it will go in its bore. You can then use a dial indicator, tape measure or ruler to measure how far the piston moves down when the crank is rotated to move the piston to Bottom Dead Center (BDC).

If an engine is assembled and you want to determine its stroke, remove a spark plug and use a small piece of stiff wire or a plastic straw to "feel" how far down the piston travels from TDC to BDC. Use a marker to mark position of the wire or straw when the piston is at TDC, and then again when the piston reaches BDC. Then measure the distance between the two marks to see how far the piston traveled.

Another method for measuring engine displacement on an assembled engine is a cylinder volume test:

It is hard to judge a book by its cover, but you can determine the displacement IF the engine is original, unmodified and you can read the engine serial number on the block or the engine VIN code on the vehicle identification plate. You can also Google the year/make/model of the vehicle to see what engine sizes were available for that application. If only one size engine was offered, its that size engine. If there were option engines such as a four, V6 or V8, just count the spark plugs to figure out which engine it is.

On applications where the same block may be used for different displacements (such as older Chevy small block and big block V8s), bores and strokes can vary quite a bit. A big block Chevy might be a 396, 402, 427, 454 or something else if the engine has been bored or fitted with a different crank. The external appearance of the engine and serial number on the block may be no help if an engine has been modified. Someone selling a used engine might also claim the engine is not what it actually is, so you may have to use a cylinder volume test to accurately determine engine displacement.

Engine displacement is simply a way of comparing engine sizes. Generally speaking, more displacement means more horsepower and torque because a larger engine is capable of pumping and burning more air/fuel mixture in its cylinders. Even so, there is no direct correlation between engine displacement and horsepower because a lot of variables affect how much power any engine of a given size will actually produce. An engine's power output depends on its "volumetric efficiency" and "thermal efficiency" as well as its horsepower and torque curves across its RPM range.

Volumetric Efficiency (VE) is how efficiently the engine breathes as it pumps air through itself. Volumetric efficiency typically ranges from 80 percent to nearly 100 percent. Engines with three or four valves per cylinder typically flow air better than those with two valves per cylinder, so they are usually have better volumetric efficiency numbers especially at higher engine speeds. An engine with two valves per cylinder will typically achieve a VE of 80 to 85 percent. An engine with four valves per cylinder will do better with a VE of 85 to 90 percent. An engine with four valves per cylinder and variable valve timing can often reach VEs in the 95 to 100 percent range.

In modified naturally aspirated street performance and race engines, VE may exceed 100 percent and be as high as 115 to 120 percent.

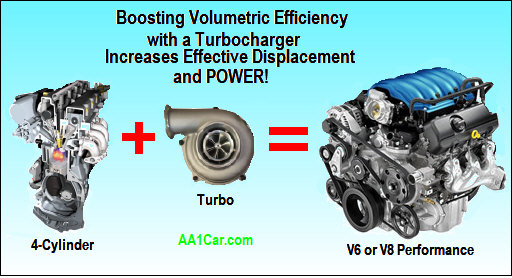

Turbocharged and supercharged engines create boost pressure to force even more air into an engine, allowing it to breathe at volumetric efficiencies that far exceed 100 percent. The higher the boost pressure, the higher the volumetric efficiency. A turbo that delivers 8 to 10 PSI of boost pressure may increase an engine's volumetric efficiency as much as 140 to 160 percent.

The formula for calculating the volumetric efficiency of a naturally aspirated engine is:

VE = (CFM x 3,456) divided by (CID x RPM)

CFM is how much air is flowing through the engine in cubic feet per minute. This can be measured with special airflow equipment on a dynamometer or estimated (see formula below). CID is Cubic Inch displacement, and RPM is Revolutions Per Minute.

To estimate how much air is flowing through an engine, use the following formula:

Estimated engine airflow in CFM = (RPM x displacement) divided by 3456

For stock street engines, multiply the estimated engine airflow in CFM by 0.85

For a naturally aspirated race engine, multiply the estimated engine airflow in CFM by 1.1.

Thermal Efficiency (TE) is how much useful power the engine makes from a given quantity of fuel burned in a cylinder. Internal combustion engines are not very efficient and typically wasting almost two-thirds of the heat energy produced by every combustion cycle. Nearly one-third of the heat energy produced during combustion goes out the tailpipe as hot exhaust. Another third of the heat energy is absorbed by the engine itself and is carried away by the cooling system to the radiator. That leaves only about a third of the energy to push the pistons down and drive the vehicle forward.

Diesel engines are more thermally efficient than gasoline engines because of their much higher Compression Ratio (16 to 1 or higher for a diesel compared to 10 or 11 to 1 for most late model gasoline engines). Higher compression ratios reduce heat losses in the combustion chamber for better fuel efficiency, power and fuel economy. However, late model Gasoline Direct Injection (GDI) engines also have higher compression ratios (some as high as 14 to 1) which makes their thermal efficiency almost as good as a diesel.

How much power an engine of a given displacement will actually generate depends on many variables, including the design of the cylinder heads and their flow characteristics, the size and number of valves per cylinder, camshaft valve lift, duration and overlap, cam timing, spark timing, the type of carburetion or fuel injection (port injection or direct injection), the air/fuel ratio at part and full throttle, the design of the intake and exhaust manifolds, engine compression ratio and type of fuel (gasoline, alcohol, gas/ethanol blends, race gas, diesel, propane or natural gas). Consequently, a "naturally aspirated" (not turbocharged or supercharged) 350 CID V8 might make anywhere from 250 to 450 peak horsepower depending on how all of these variables affect volumetric and thermal efficiency.

In a boosted engine (one with a turbocharger or supercharger), additional air can be forced under pressure into the engine on demand. This trick makes a small displacement engine breathe and produce power like a much larger displacement engine. If you use a turbo or supercharger to cram 50 percent more air into an engine, it should make about 40 to 50 percent more power. This allows a turbocharged 2.0L four-cylinder engine to perform like a much larger V6 or V8 engine.

Ford's 2.3L Ecoboost (turbocharged) four-cylinder engine in late model Mustangs uses up to 20 PSI of boost pressure to generate 310 horsepower and 350 lb. ft. of torque, which is equivalent to the horsepower and torque of a stock naturally aspirated 4.6L V8. As an added benefit, the smaller displacement turbocharged engine delivers much better fuel economy than a V6 or V8 because it only uses the extra boost pressure when the car is accelerating. That is why so many late model vehicles no longer have a V6 or V8 engine. The auto makers have gone to smaller displacement turbocharged engines to boost fuel economy without sacrificing performance.

In a naturally aspirated engine, air is "sucked" into the engine when the pistons move down on their intake stroke. Atmospheric pressure (14.7 PSI at sea level) pushes the air through the intake system and into the engine to fill the void (vacuum) created in the cylinders when the pistons move down in their bores. Consequently, a naturally aspirated engine can only inhale a volume of air equal to or less than its actual displacement. How much air it actually uses depends on its volumetric efficiency and the throttle opening.

Most naturally aspirated passenger car gasoline engines operate at around 85 percent volumetric efficiency. A modified raced engine may achieve 95 to 100 percent efficiency, and some can even exceed 100 percent efficiency by using the ram effect of incoming air flow to cram more air into the cylinders. Long intake runners (such as a tunnel ram manifold) create a lot of momentum as the air flows down into the engine. Increasing the duration (open time) of the intake valves will allow more air to fill the cylinders. Likewise, increasing valve overlap (the period during which the exhaust valve is still closing while the intake valve is opening) creates a siphoning effect that helps pull more air into the cylinders. The next result is that with the right tuning, a highly modified naturally aspirated engine might achieve 110 to 115 percent volumetric efficiency at high RPM.

Bolt on a turbo or a supercharger, then crank up the boost pressure and you can overcome the limitations of air flow and make as much power as the engine can safely handle. At some point, however, cylinder pressures will exceed the strength limits of the stock block, pistons, connecting rods and crank which means these components will have to be beefed up with stronger aftermarket performance parts. Such modifications can transform a stock small displacement four cylinder into a 1000-plus horsepower monster!

The relative ratio of bore to stroke is another factor in engine displacement that affects engine power, torque, fuel economy, emissions, internal friction and RPM potential.

Generally speaking, an engine with a larger bore and shorter stroke (a stroke/bore ratio less than 1) will rev higher and produce more top end power. An engine with a bore that is larger than its stroke is called an "over square" engine.

An engine where the bore and stroke are equal (a stroke/bore ratio of 1 to 1) is called a "square" engine.

An engine where the stroke is larger than the bore (a stroke/bore ratio greater than 1) is called an "undersquare" or "long stroke" engine. A long stroke engine will typically produce more low speed torque but won't rev as high. A longer stroke engine also creates more reciprocating forces as the pistons and rods move up and down. This increases the stress on the rods and crank. It may also require a physically taller block whereas a short stoke engine can have a shorter, more compact block.

Although a shorter stroke reduces the leverage of the rod journals on the crank (a longer throw provides more leverage and thus more torque multiplication), a shorter stroke also means the pistons have less distance to travel with each revolution of the crankshaft. This reduces piston to cylinder friction (less piston ring drag), piston velocity and stress. It also allows faster filling of the cylinder during the intake stroke because the pistons travel a shorter distance, and it allows faster pumping of the exhaust gases out of the combustion chamber during the exhaust stroke. As a result, a big bore short stroke engine will usually make more horsepower than an engine with identical displacement that has smaller bores and a longer stroke.

Most Formula One racing engines have extremely short strokes (maybe only 1.6 inches versus 4 inches for a typical stock V8). The extremely short stroke allows them to rev to 15,000 RPM or higher (compared to 6500 to 7000 for a typical stock V8).

This is why racers will typically build an engine with the largest possible bore and a shorter stroke if rules limit total engine displacement for a given class of race car. They may also vary the bore and stroke ratio somewhat for the same displacement depending if a car is racing on a short track or long track, and where peak power and torque will do the most good.

Boring out a cylinder to a larger dimension will increase overall engine displacement and the compression ratio of the cylinders, which usually provides an increase in power. However, most late model engines have relatively thin cylinder walls to reduce weight, and are not designed for overboring or rebuilding. Many late model engines with aluminum blocks have iron or steel cylinder sleeves. The sleeves may be press fit or cast in place. Press fit sleeves can be removed and replaced if worn, but cast in place sleeves cannot be removed. You have to cut them out and install special replacement sleeves or replace the block entirely. Some late model aluminum blocks do not use iron or steel sleeves but instead have a special hard nickel/chromium plasma coating on the cylinder walls for wear resistance. Coated cylinders can be bored but must then be fitted with sleeves unless special plasma spray equipment is used to reapply the hard surface coating after boring.

By comparison, most older engines with cast iron blocks have thick enough cylinder walls to allow a certain amount of overboring. Most of these older iron blocks can be safely bored to .030 inches oversize, while others can be bored up to .060 inches or more. Aftermarket performance cylinder blocks with thicker cylinder walls are also available for custom sizing cylinder bores. Most of these use iron or steel pressed-in sleeves are cylinder liners.

Many large diesel engines have "wet liners" for cylinders. These are heavy iron or steel sleeves that are not supported by an outer cylinder bore. The liner itself is the cylinder bore and is in direct contact with the coolant. Wet liners are used in large diesel engines so they can be replaced to repair a damaged cylinder or when rebuilding the engine.

When the cylinders in an engine block have been bored to oversize, the original pistons will no longer fit so they must be replaced with larger oversized pistons. The height of the pistons and the configuration of the top of the pistons (flat, domed or dished) will determine the compression ratio. Pistons with a dished or concave top will lower the compression ratio while pistons with a domed top will increase compression. Changing the thickness of the head gasket can also increase or decrease compression as can milling the cylinder head or installing heads with different volume combustion chambers (smaller chambers increase compression while larger chambers decrease compression).

Replacing a stock crankshaft with a "stroker" crank that has longer rod journals will also increase cylinder volume and overall engine displacement. Stroker cranks are good for street performance because they provide more low and mid-range torque and power. But because the rod throws are longer, it may create interference problems between the big ends of the rods and block. This, in turn, may require grinding away some metal on nearby block surfaces to produce adequate clearance.

A stroker crank also requires shorter connecting rods and/or pistons (or pistons with the wrist pins relocated higher in the piston body) so the tops of the pistons do not hit the cylinder heads.

The amount of Carbon Dioxide (CO2) produced by an engine is directly proportional to its displacement and fuel consumption. The larger the engine, the more CO2 it produces with every gallon of fuel it burns. Although fuel economy has been the primary driving force for engine downsizing in recent years, reducing engine displacement also helps reduce CO2 output and the global warming effects attributed to CO2 from cars and trucks.

This is not an insignificant change because the world car population now exceeds 1.5 BILLION vehicles!

The use of smaller displacement turbocharged engines is having a positive impact on reducing both fuel consumption and CO2 emissions. Unfortunately, many of the gains in CO2 reduction that are being provided by using smaller engines in late model vehicles is being offset by the huge growth in the car populations of China, India and other developing nations.

For more information on this subject, see How CO2 Emissions Affect Climate Change and Global Warming and Climate Change.

Related Engine Articles:

Related Engine Articles: Click Here to See More Carley Automotive Technical Articles

Click Here to See More Carley Automotive Technical Articles